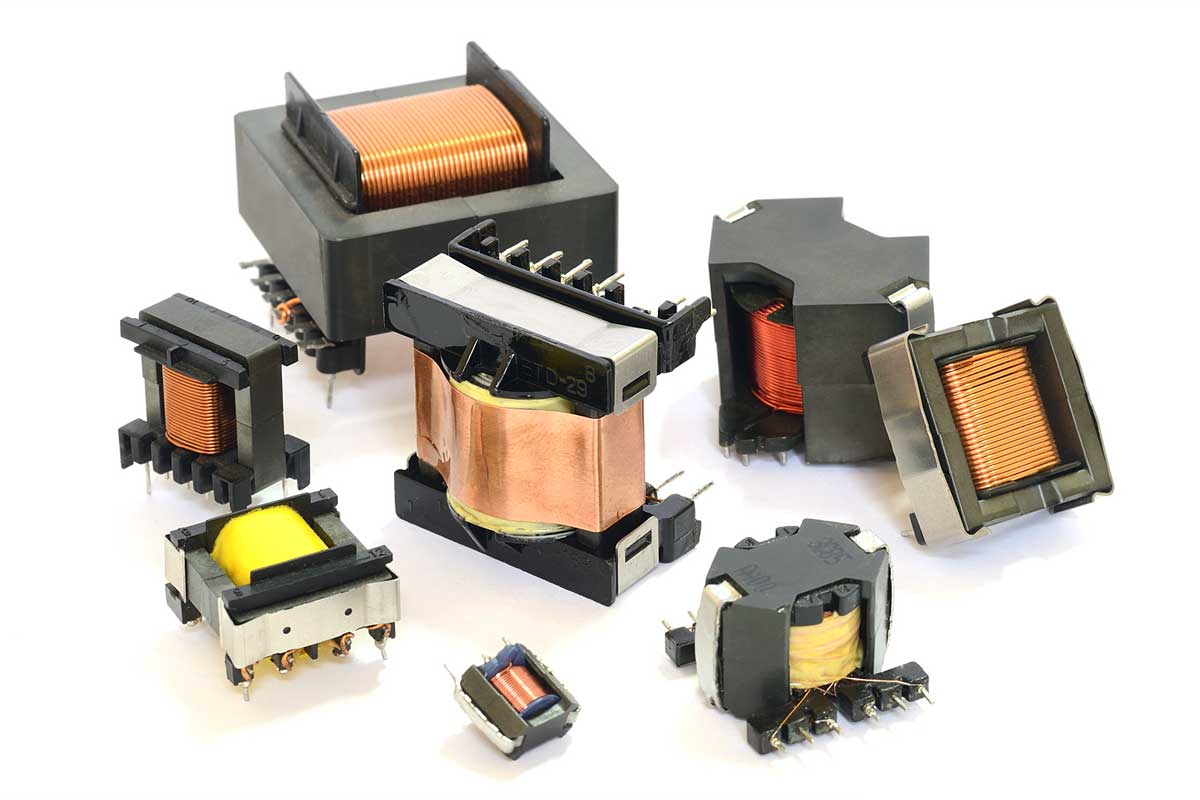

TELZAM manufactures various types of transformers. Most of the products are made for individual orders and according to the requirements of the customers. These are often the development of our designers and implementation departments. Transformers are made on ferrite cores like RM, EFD, ETD, EE, EP, PC, U and others. Variety of cores from which transformers are made are matched to power transmission and optimum use of PCB space. We wind windings in transformers with enamelled wires in single, double and sometimes even triple enamel and wires in triple insulated TEX-E (TIW), Cu copper strips, HF faces. In addition, winding windings with several wires at the same time (connected in parallel) to eliminate the “skin effect”. We eliminate interference and improve security by using copper shield screens where the internal screen is placed between the primary winding and the secondary winding, and the external screen includes the winding together with the core.

Impulse transformers

are used in all power supply configurations as well as in applications as separating transformers. They are also used in electric lighting fixtures. The TELZAM pulse transformers operate on frequencies from several dozen to 500kHz and are performed on different sizes of EE, ETD, EFD, EP, P, RM, etc. cores.

The transformers manufactured by our company are adapted to the electronics of the power supply. Based on our experience, each time we consult with a client, we try to offer the optimum solution.

Separation transformers and transformers

are made on RM, EP, ETD, EFD, P, toroidal and other cores. The task that meets this galvanic separation, ie galvanic separation of printed circuits. Wide range of applications are in the transmission transmission equipment transformers with a gear ratio of 1: 1.